Machine shielded metal arc welding machine is the main parts of this process because without machine certainly we can not do welding process.

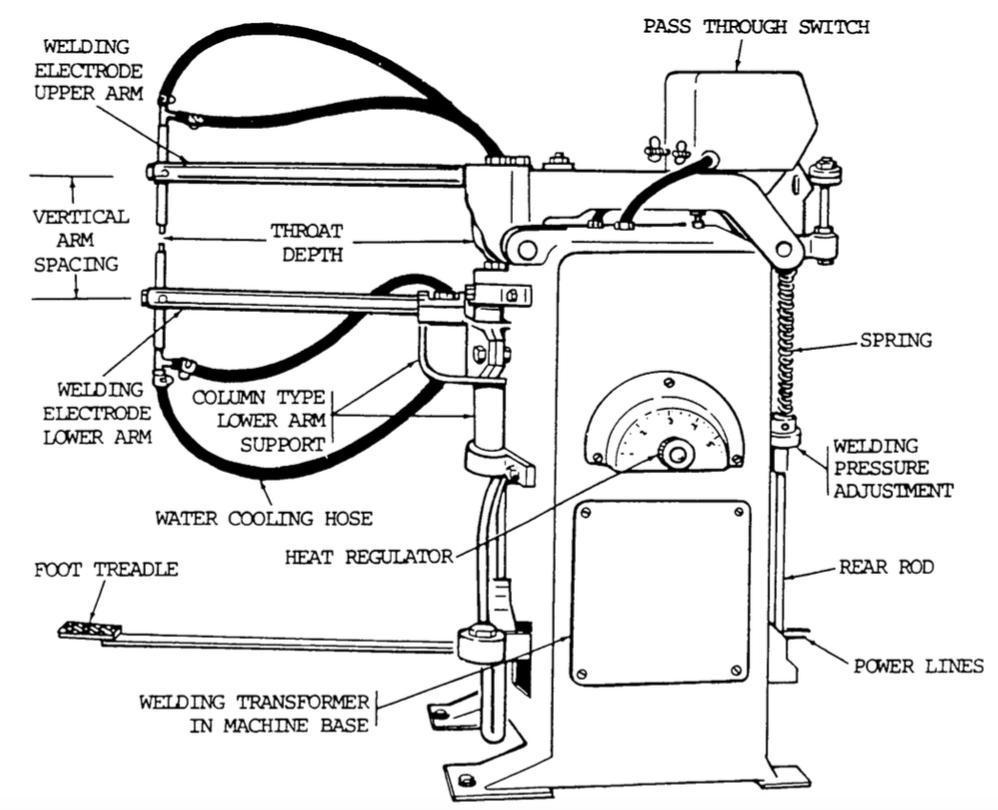

Spot welding machine parts and function.

They are available in a variety of sizes and output voltages from a small hobby model with an 80 amp output to an industrial model with a 12 000 amp output for spot welding.

Spot welding electrodes are available in different shape size offset and diameter with iso and morse taper to suit.

The tool holders function as a mechanism to hold the electrodes firmly in place and also support optional water hoses that cool the electrodes during welding.

A small change of one parameter will effect all the other parameters.

This squeezing pressure is controlled.

The determination of appropriate welding parameters for spot welding is a very complex issue.

The 240volt t spot 110 machine is designed to repair steel car bodies with special regards to sheet metal straightening rivets welding and localized heating with carbon electrode.

Due to our proficiency with brnad parentnashik we are involved in offering the first class series of resistance spot welding double bend electrodes for spot welding gun robotic welding portable welders prior to dispatch presented product is tested against varied parameters.

This and the fact that the contact surface of the electrode is gradually increasing makes it difficult to design a welding parameter table which shows the optimum welding.

It can be controlled by a foot pedal.

It comes with functions like battery testing and battery charging.

This spot welding machine is suitable for welding 0 1 0 2 mm nickel plated steel strips.

The selection button on the multi function gun remotely allows the programs quick selection of pre set parameters and fine adjustment.

The equipment used in the spot welding process consists of tool holders and electrodes.

Welding machines are used to permanently connect metal pieces with heat generated from electrical energy.

Tool holding methods include a paddle type light duty universal and regular offset.

The pieces to be welded are heated by passing welding current through them.

The feeding system welding and forming system cutting system and control panel are all set on the main body.

Electrode cable the function electrode cable connects the current from welding machine to electrode which we use to weld the base metal.